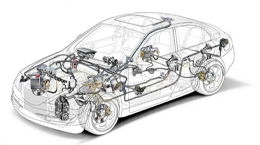

I think we can all agree that the automotive industry is transforming fast, driven by a growing consumer demand for sophisticated digital features and increased environmental regulation. The average passenger car today relies on between 50-75 embedded electronic modules to monitor and control nearly all aspects of vehicle operations. From steering/braking, tail-pipe emission controls, and safety, to entertainment and comfort enhancements, it is vital to ensure the safe and reliable operation of these systems.

Immunity Testing in the Automotive Industry

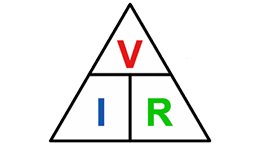

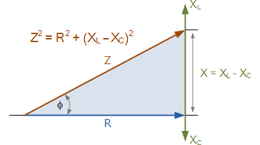

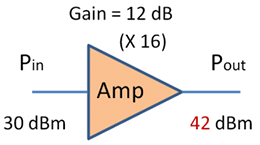

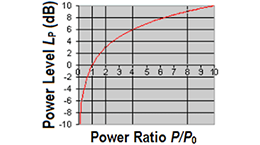

Electromagnetic compatibility refers to a device’s ability to function properly in its intended electromagnetic environment without interfering with other devices or equipment nearby. EMC testing is the process of ensuring that a device meets these standards. All vehicle original equipment manufacturers (OEMs) and most component suppliers rely on EMC and electrical testing to confirm that a vehicle will operate properly in the presence of its own interference as well as from other devices.

Immunity testing measures how well a device can withstand electromagnetic interference from external sources. The tests simulate real-world scenarios where a device may be exposed to strong electromagnetic signals such as power surges or lightning strikes. The goal of this test is to ensure that the device continues to function properly even in the presence of strong electromagnetic signals.

Why Perform Pre-compliance Immunity Testing?

EMC pre-compliance testing was created to identify potential problems early in your design process, before full-scale testing takes place. This can be very helpful in avoiding inconvenient product redesigns that can result when testing is put off until the final phase of the design process.

Utilizing early-stage in-house pre-compliance testing and test data will increase your confidence that your product will pass when it’s eventually sent out-of-house for full compliance certification. Initiating in-house pre-compliance test methods as early as possible, instead of at the end of the product development program will result in saved time and money.

While pre-compliance immunity testing may seem like more of a hassle than it’s worth, it exists for several reasons:

- Detects errors early, fixing potential issues

- Lowers testing and design costs

- Projects stay on schedule

- Lowers risk of failure and leads to assured compliance

- Reduces future warranty issues

What Happens When You Don’t Comply?

During development, many engineers and designers emphasize performance, reliability, form, function, and even appearance. Despite its importance, compliance is sometimes last on that list.

No matter how hard you try, you can’t plan for everything. This is why it’s better to take pre-compliance steps, so you can have confidence that your product or equipment will be ready and compliant when it’s time to launch and avoid the following consequences:

- Non-compliant products could be stopped at customs

- Fines and repercussions due to non-compliance

- Multiple testing submissions result in excessive costs

- Damaged product and brand reputation

- Decreased reliability and safety

How AE Techron Can Help

We understand that EMC testing for the automotive market can be daunting. it’s not unusual for new products to fail initial full-scale compliance testing. In fact, nearly 50% of products fail EMC testing during the first round.

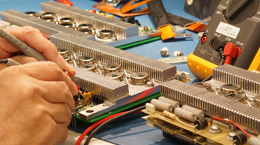

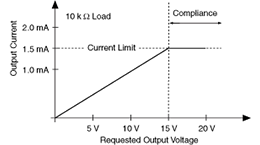

Which is why we have developed a complete, single-box solution for immunity testing. AE Techron’s DSR 100 Series includes everything needed for conducted immunity testing, including:

- a simple-to-use, yet powerful, standards waveform generator

- an industry leading power supply technology

- 2,200+ extensive library of tests for many automotive and industry standards

- models from 25A to 150A continuous output current

So why wait to start your own in-house pre-compliance testing? The value is clear and the right tools are available from AE Techron.